Marine gasketed plate heat exchangers

Alfa Laval has been developing heat transfer technology for more than 80 years and has been active in the marine industry for over a century. Based on that vast wealth of experience, our engineers have designed gasketed plate heat exchangers that set entirely new standards – not only for reliability, but also for thermal performance and ease of service.

The marine industry’s most modern line of plate heat exchangers

- Superior reliability and energy efficiency (OmegaPort™ ) (FlexFlow™ )

- Small size and footprint (CompactFrame™ design)

- Minimal fouling (CurveFlow™ plate distribution area)

- Easy installation and service (five-point alignment system)

- Optimized global supply chain and production for smallest environmental footprint

Suitable for any vessel, Alfa Laval gasketed plate heat exchangers excel in applications from general heating and cooling to heat recovery, condensation and evaporation. Whether used as central coolers in the engine room or for glycol heating onboard Floating Supply and Regasification Units (FSRU) their innovative features, take reliability to an all-new level and save crews time and effort during maintenance. Above all, their design minimizes fouling and maximizes heat transfer capabilities, which ensures the highest possible energy efficiency.

Learn more about the CompactFrame™, CurveFlow™,

Five-point alignment and other features that make the difference.

Produkty

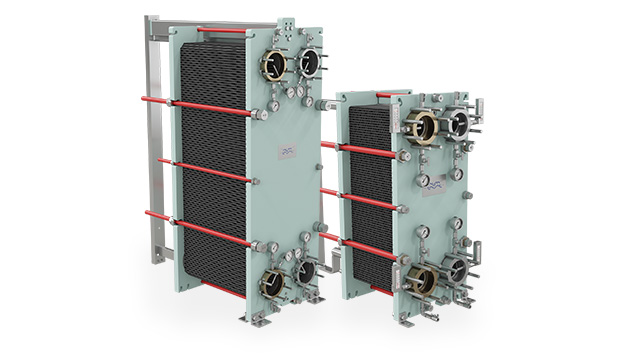

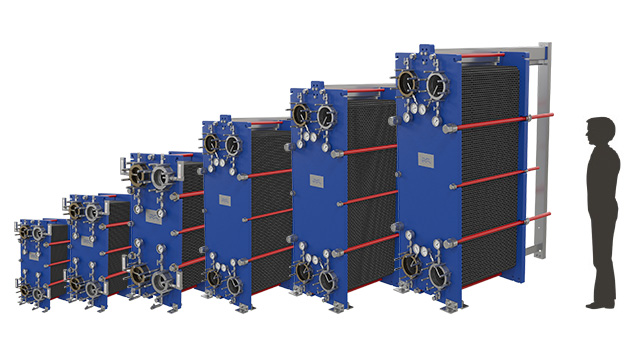

Gasketed plate heat exchangers for the engine room (central coolers)

Compact, reliable and energy-efficient, Alfa Laval gasketed plate heat exchangers are also safe and simple for crews to maintain. Our flexible marine line provides the right match for your needs today – with the possibility to adjust capacities later.

| T6 DN 60 |

T10 DN 100 |

T15 DN 150 |

T21 DN 200 |

T25 DN 250 |

T35 DN 350 |

|

|---|---|---|---|---|---|---|

| H (mm) | 890 | 1054 | 1833/1781 | 2082 | 2761 | 2875 |

| W (mm) | 320 | 470 | 610/650 | 755 | 913 | 1174 |

|

Temperature (oC) |

0 to 150 |

0 to 150 |

0 to 180 |

0 to 100 |

0 to 100 |

0 to 100 |

|

Pressure (bar) |

16 |

16 |

16 |

10 |

10 |

8 |

| Max flow rate (m3/h) | 60 | 160 | 370 | 650 | 1000 | 1970 |

| Capacity (kW) – water duty with LMTD 6 | 800 | 3 000 | 9 000 | 18 000 | 28 000 | 35 000 |

XL marine gasketed plate heat exchangers for glycol heating onboard Floating Supply and Regasification Units (FSRU)

|

|

|

|

|

|

TS45 |

T45 |

T50 |

|

|

H (mm)* |

2745 |

3540 |

4010 |

|

W (mm)* |

1430 |

1420 |

1550 |

|

Temperature (oC) |

- 50 to 150 |

-50 to 150 |

- 50 to 150 |

|

Pressure (bar) |

15 |

15 |

16 |

|

Max flow rate (m3/h) |

2 000 |

3 200 |

4 400 |

|

Capacity (kW) – water duty with LMTD 6 |

45 000 |

45 000 |

55 000 |

*Frame plate

Jak to funguje

Teplosměnná plocha rozebíratelných deskových výměníků tepla sestává z několika vlnitých desek zabudovaných mezi rámovou a přítlačnou desku tak, aby zachovávaly tlak. Těsnění desky utěsňují. Kapaliny standardně výměníkem tepla protékají protisměrně. Toto uspořádání zajišťuje největší možný tepelný výkon. Zároveň umožňuje využití metody malého rozdílu teplot, kdy je teplotní rozdíl mezi vystupujícím procesním médiem a vstupujícím servisním médiem minimální.

Rozebíratelný deskový výměník tepla Alfa Laval s rámem typu kapalina-kapalina

Features that make the difference

The Industrial line is equipped with features that turn this high-performance family into efficient and reliable workhorses that are easy to service and maintain over the whole product lifecycle.

For efficiency

By improving the efficiency of your heat exchanger, you can maximize production and minimize energy consumption to reduce your power bill and improve your environmental footprint.

See product animations below or get more information and listen to our technical experts.

Distribuční oblast

Distribuční oblast

CurveFlow™

Zlepšuje proudění médií a minimalizuje riziko znečištění.

Nepravidelné otvory portů™

Nepravidelné otvory portů™

OmegaPort™

Podporují proudění médií a tepelnou účinnost.

FlexFlow™

FlexFlow™

plate design

Improves thermal efficiency and optimizes pressure drop utilization.

For reliability

We are always looking to increase the reliability of every aspect of our gasketed plate heat exchangers.

We focus on durable designs based on robust materials and safe manufacturing processes.

See product animations below or get more information and listen to our technical experts.

Rozdělení vzoru desky

Rozdělení vzoru desky

PowerArc™

Zvyšuje tuhost desky a tím prodlužuje životnost zařízení.

5 bodový systém vedení desky

5 bodový systém vedení desky

Zajišťuje spolehlivé slícování desek a usnadňuje servis velkých zařízení.

Zarovnání desek

Zarovnání desek

SteerLock™

Zajišťuje spolehlivé slícování desek a usnadňuje servis zařízení.

For serviceability

The simple opening and closing of the plate-and-frame design with gaskets enables hassle-free inspection and service. It also enables you to easily adapt the unit to new process conditions.

See product animations below or get more information and listen to our technical experts.

Tesnění

Tesnění

ClipGrip™

Zajišťuje dokonalé utěsnění a bezproblémovou údržbu.

Pojezd přítlačné desky

Pojezd přítlačné desky

pod horní nosnou tyčí

Nižší výška výměníku tepla a následná snazší údržba.

Ložisková hlava

Ložisková hlava

Zaručují snadné otevírání výměníku a následně snazší a efektivnější údržbu.

Kompaktní rám

Kompaktní rám

Usnadňuje údržbu a minimalizuje prostorové požadavky při servisu.

Case stories

Alfa Laval technology powers sustainable operations on Maersk’s pioneering methanol-fuelled container vessel

In a world where sustainability is increasingly important, A.P. Moller-Maersk has set sail with the world’s first methanol fuelled container vessel. Equipped with Alfa Laval’s solutions for methanol as fuel, this vessel shows how innovative solutions and equipment can help shipping companies adapt to the evolving energy landscape and environmental regulations.

Documents

Instructions and manuals

Product brochures

Heating and cooling in an engine room

On a ship, there are many types of machinery with a cooling demand. When the heat energy cannot be recovered or utilized, the total costs of transferring it away from the machinery should be kept to a minimum. Alfa Laval can ensure a cost-effective central cooling system through our portfolio of innovative plate heat exchangers. Our gasketed plate heat exchangers have unique features that reduce the running costs for engine room cooling – and contribute to sustainability.

Services

Alfa Laval Marine Service

Worldwide and 24/7, Alfa Laval Marine Service is your path to greater uptime, optimized performance and true peace of mind. Our network is always on call, and our service offering brings reliability, efficiency and compliance throughout your equipment's lifetime.

24/7 Service & Support

Contact us anywhere, anytime:

+46 4636 7700

marine.service@alfalaval.com

Our global network of service centres centres, distribution centres and field service engineers is always ready at assist you.