ALF

The Alfa Laval Filter, or ALF, is a self-cleaning filter that is designed to protect heat exchangers from clogging, fouling, and corrosion in various industries that use secondary water in the cooling systems. By removing debris and marine life, this industrial water filtration solution reduces the risk of unplanned downtime and prolongs heat exchanger service intervals. This efficient heat exchanger protect solution also increases energy efficiency, reduces CO2 emissions, and saves OPEX.

Features that make water filtration efficient:

- Proven, reliable filtration technology

- One of the most compact self-cleaning filters on the market

- Easy installation and low maintenance

- High filter capacity with low-pressure drop

- Automatic backflushing without interrupting the filtration process

- Full, lifecycle support from Alfa Laval service

- Pairs with all Alfa Laval plate heat exchangers and tubular condensers

Why do you need ALF in a secondary cooling system?

1. Increase efficiency

Fouling, clogging, and corrosion can significantly reduce the efficiency of heat transfer, limiting the speed at which secondary water can flow through any given heat exchanger. This often leads to a build-up of biological growth and surface fouling.

The Alfa Laval Filter (ALF) is a cost-effective way to avoid all these problems and ensure a reliable supply of clean cooling water. This is thanks to automatic intervening flushes that do not interrupt or disturb the filtering process or cooling operations in any way.

2. Cost Reduction

With a lower pressure drop across both plate heat exchanger and filter, an ALF installation helps reduce the overall costs of an effective cooling package without compromising on high capacity. And, thanks to very few moving parts, even the maintenance costs are low.

3. Installation flexibility

The ALF pressure filter has a casing made of stainless steel (ALF-S model), fibreglass-reinforced polyester (ALF-P) or rubber-lined carbon steel (ALF-R and ALF-B), and an internal cylindrical filter basket made of stainless steel. That means that a range of different material specifications and mesh sizes are available to fit your installation.

The ALF design has the inlet directly in line with the filter and the outlet at a 90º angle. This provides easy access to the filter basket without removing the connections, making it ideal for installation on any 90º pipe bend.

Jak to funguje

ALF is designed to maintain the thermal performance of plate heat exchangers and tubular condensers by making sure there is no debris or other undesirable materials in the secondary cooling systems. It works using highly effective automatic flushing set-up that can function automatically at predetermined intervals, or manually by pushing a button on the control panel.

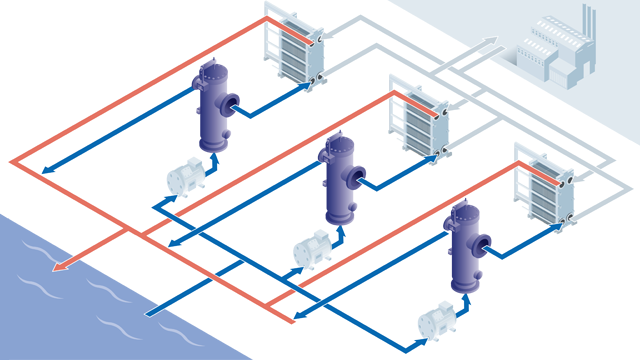

Secondary cooling systems that use inexpensive, low-grade water have become widely accepted in many industries. But, lower-grade water can often contain undesirable particles, organisms, and debris that foul or clog the plate heat exchangers and tubular condensers used in such cooling set-ups.

In a typical secondary cooling system, the ALF filter is always installed downstream from the pump and upstream from the heat exchangers, making sure that there is no debris, or other undesirable materials, in the cooling water. The ALF can either be horizontally or vertically implemented for easier installation.

Process animation

- During normal operation, the flow diverter is open, and the flushing valve is closed. The secondary water is filtered in the basket before entering any heat exchangers.

- In primary flushing, the flushing valve opens the flushing outlet, loosening the debris sticked to the pipe wall and the filter basket. The debris is then flushed out through the flushing outlet.

- In secondary flushing, also known as backflushing, the flow diverters close and the flushing valve remains open. Any dislodged material can then be discharged through the flushing valve.

Selected filtration cases

Data Center Cooling, Italy

To secure high-level performance and efficiency, whilst considering the specific needs of the groundwater cooling system, Alfa Laval provided tailor-made solutions with gasketed plate heat exchangers (GPHE) and 46 x Alfa Laval ALF 10-S for protection of river water cooled GPHEs.

Gas Production in Middle East

110 x Alfa Laval ALF 60-R for protection of sea water cooled gasketed plate heat exchangers.

Power generation in South America

4 x Alfa Laval ALF60-R for protecting condensers.

Wind Turbines HVDC platform, Offshore North Sea

2 x Alfa Laval ALF 40-R for protection of sea water cooled gasketed plate heat exchangers.

Amino acid production in Southeast Asia

5 x Alfa Laval ALF60-R for protection of sea water cooled gasketed plate heat exchangers.

Steel production in Europe

2 x Alfa Laval ALF 80-R for protection of sea water cooled gasketed plate heat exchangers.

Sugar production in Europe

8 x Alfa Laval ALF30-S for raw sugar juice filtering.

Marine vessel engine cooling

More than 200 x Alfa Laval ALF 20-R / ALF 30-R for protection of sea water cooled gasketed plate heat exchangers.

Fill out this form and one of our filtration experts will contact you.

You can join #nofilter challenge by sharing with us the condition of your heat exchangers. It's also a good time to reach out if any filtration support is needed.

Energy efficiency

How can Alfa Laval maximize your energy efficiency? Learn about how our solutions make it possible for our customers to reduce their capacity needs by 100 GW a year – reducing CO2 emissions by as much as 25 million tonnes. That’s 550 times Alfa Laval’s own carbon footprint.