Optimizing electrolyser cooling processes

A significant part of the future hydrogen demand is estimated to be produced in electrolysers (alkaline/PEM/solid oxide). Maximizing the efficiency and lifetime of these hydrogen electrolysers will be crucial for decarbonization. In today’s technologies, 20-40% of the hydrogen electrolyser capacity is turned into excess heat that needs to be continuously cooled off.

No matter if it’s the commercial electrolyser technologies on the market today, or the ongoing development of the next generation of electrolyser, optimizing the electrolysers cooling as well as the hydrogen plant itself is a key success factor for efficient and scalable green hydrogen production.

Energy efficient green hydrogen production

When renewable electricity is splitting water molecules into hydrogen and oxygen in an alkaline/PEM electrolyser, a large part of the electrolyser capacity is turned into excess heat. By cooling off the heat in an efficient, compact and scalable way – we not only maximize the efficiency and lifetime of the hydrogen electrolyser itself, it also allows for further repurposing of this excess heat.

By not letting excess energy go to waste, the overall efficiency of green hydrogen production can increase.

Hydrogen plants: We understand reducing OpEx and CapEx is mandatory to ensure a cost competitive green hydrogen production. With Alfa Laval’s heat transfer technology, we enable a lower levelised cost of hydrogen.

- Reducing costs

- Enabling heat recovery

- Productivity first

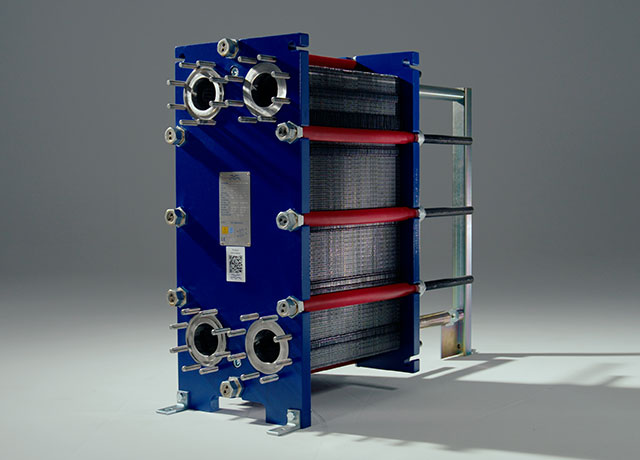

Heat exchanger tech: The new generation of Alfa Laval semi-welded plate heat exchangers takes pressure weighting to the next level, designed for optimised performance to guarantee a reliable operation in the electrolyser system.

- Handles high pressure

- Flexible configuration

- Space saving

Service solutions: Equipment used in hydrogen production must be handled in a very careful manner. Connected services ensure safety by monitoring the health status of the plate heat exchanger as well as prolonging the lifetime of the equipment.

- Ensure safety

- Accelerate sustainability

- Efficient for decades

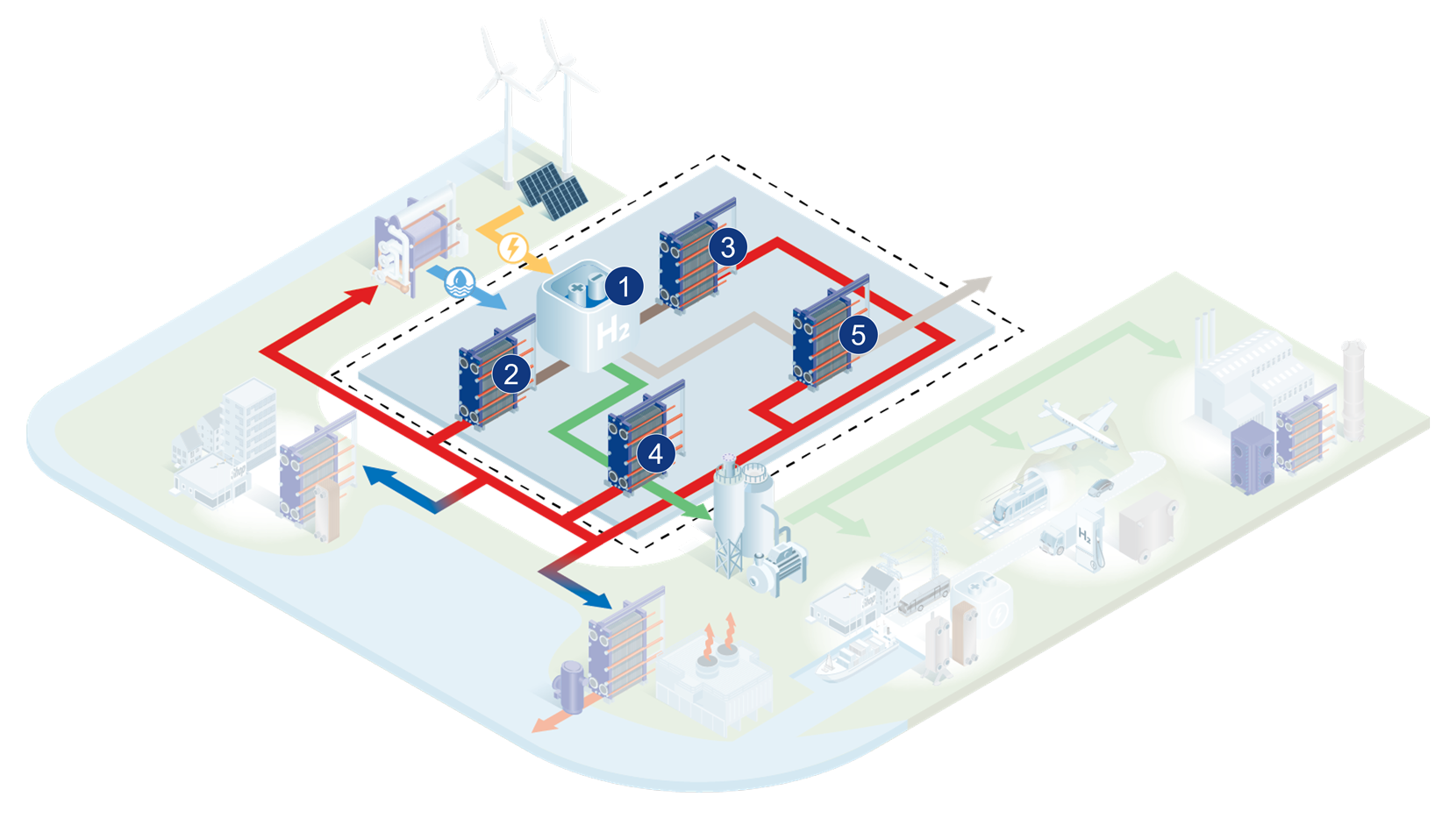

Efficient cooling electrolyser system with Alfa Laval heat exchangers

The electrolyser stack(1) is the core of the process, where the electricity is concentrated and the water is electrolysed into this most simple elements—hydrogen and oxygen. To maintain efficiency and extend equipment lifespan, temperature control is essential. This is where the anolyte coolers (2)and catholyte coolers (3)come in, ensuring the stack remains at optimal temperature by removing waste heat generated during electrolysis. Alfa Laval heat exchangers are perfectly suited for this task, not only maintaining system stability but also enabling heat recovery for added efficiency.

Beyond the electrolyte cooling, hydrogen gas coolers (4)and oxygen gas coolers(5) play a crucial role in green hydrogen production. By reducing gas temperatures to the lowest possible levels, they help optimise overall efficiency. Alfa Laval’s robust heat exchangers ensure safe operation while also offering the opportunity to recover heat from the gases, making the process even more energy efficient.

Electrolyser stack

1. Electrolyser stack

Electrolyte coolers

2. Anolyte cooler

3. Catholyte cooler

Gas coolers

4. Hydrogen gas cooler

5. Oxygen gas cooler

Whitepaper: Turning up the heat

"Turning up the heat - proven solutions for using waste energy from electrolysers" explores innovative solutions and collaborative efforts that utilize this untapped potential, to drive the hydrogen industry towards a sustainable net-zero future by 2050.

Zelený vodík dává naději do budoucna

Zelený vodík je již dlouho nadejí pro dosažení evropských cílů v oblasti klimatu. V Německu nyní ukazuje nový pilotní projekt potenciál, který může být realizován. Společnost Thyssenkrupp Uhde Chlorine Engineers GmbH testuje pomocí výměníků tepla Alfa Laval vodík namísto vstřikování uhlí, aby snížila emise CO2 při provozu vysokých pecí ve svém závodě v Duisburgu. Jediné, co po tomto novém procesu zůstává, je vodní pára.

Tento projekt, který financuje německá vláda, využívá hutní plyny vznikající při výrobě oceli k výrobě chemických látek, čímž snižuje emise CO2 při výrobě oceli i při výrobě chemických látek. Podívejte se na celý příběh a dozvíte se více o zásadní roli, kterou v tomto pilotním projektu sehrála technologie Alfa Laval.

Supplies the world’s largest green hydrogen plant

Alfa Laval has signed an agreement to deliver compact heat exchangers to the world’s largest green hydrogen plant, which is to be constructed in the Middle East. The facility, powered by renewable energy, will be part of the city of Neom, built from scratch in the northwestern desert, with the ambition of establishing a new model for sustainable living.

Alfa Laval’s offering in green hydrogen production

Alfa Laval Semi Welded Heat Exchanger

- Highly efficient and flexible

- Space-saving compact unit

- Low operating cost possible owing to superior energy efficiency and prolonged service intervals

- Safe and reliable sealing with no risk of cross-contamination

- Pressure and temperature fatigue resistant

Alfa Laval Industrial GPHE

Meet with modern requirements

- Highest thermal efficiency and close temperature approach

- Compact units - space saving, easy to service and maintain

- Maximum uptime - less fouling, stress, wear and corrosion

- Flexible - easy to adapt to changed duty requirements

Alfa Laval ALF filter

For all Alfa Laval heat exchangers

- Automatic backflushing for uninterrupted filtering process

- Easy installation and maintenance

- Increased cooling system uptime and lower maintenance costs

- Proven, reliable technology

Contact us for more efficient green hydrogen production

We have more experience in green hydrogen production and scaleup to share with you. Contact us today for further information and partner up with us for a more sustainable future.

Energy efficient clean hydrogen solutions

Do you want to know more about how Alfa Laval supports in development in the full hydrogen value chain? Explore our offerings in everything from production to end-use.

Water purification for clean hydrogen production

Water quality is a crucial aspect to optimize green hydrogen production. Combined with increased energy efficiency makes it even more important. Find out more about what Alfa Laval can offer in water generation for clean hydrogen production.